|

Shanghai Niel Machinery Manufacturing Co.,Ltd

|

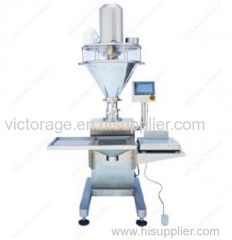

Product Description of Auger Conveyor

| Price: | 10000.0 USD |

| Payment Terms: | T/T,L/C,Paypal |

| Place of Origin: | Shanghai, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Product Description of Big Bag Packing System

Auger conveyor is also called material hoist. The vibrating screw feeder can lift a variety of powder materials. The material box and the auger are made of stainless steel. The vibration amplitude of each switch motor and vibration motor can be adjusted.

Product Description of Auger Conveyor

The whole spiral can be easily disassembled, cleaned and automatically fed, and automatically stopped; the spiral and the soft connection between the barrel and the silo are easy to disassemble; the lower end of the barrel has a flap and a positive and negative switch for easy cleaning; the silo is equipped with a vibration motor , the material automatically enters the screw.

Working Principle of Auger Conveyor

When the auger shaft rotates, due to the gravity of the material and the friction generated by the wall of the tank, the material can only move forward along the bottom of the conveyor under the pushing of the blade, and the situation seems to be that the nut can not be rotated. The rotating screw acts as a translational motion. The movement of the material in the intermediate bearing is based on the thrust of the material moving forward. Therefore, the transport of materials in the conveyor is completely a slip motion. In order to make the screw shaft in a more favorable tension state, the driving device and the discharge port are generally placed at the same end of the conveyor, and the feed port is placed as close as possible to the tail of the other end. The rotating spiral blade conveys the material and the force of the material not rotating together with the screw conveyor blade is the weight of the material itself and the frictional resistance of the screw conveyor casing to the material. The shape of the blade has a solid surface type, a belt surface type, a blade surface type and the like depending on the material to be conveyed. The screw shaft of the screw conveyor has a thrust bearing at the end of the material moving direction to give the axial reaction force of the spiral with the material. When the length of the machine is long, the intermediate hanging bearing should be added.

Application of Auger Conveyor

Food powder

Chicken powder

Flour or other grain powder

Medicine powder

Chemical powder

Granule materials

Main Features of Auger Conveyor

(1)Power supply: 3PAC208-415V 50/60HZ

(2)Charging angle: Standard 45 degree, 30-60 degree are also available

(3)Charging Height: Standard 1.85M,1~5 M could

be designed and manufactured

(4)Square hopper, with a vibrator, Round hopper could be designed and manufactured

(5)Fully stainless steel structure, contact parts

SS304

Remark: Other Charging Capacity could be designed and manufactured

Technical Data of Auger Conveyor

Technical Data | ||||||

Model | NSF-2 | NSF-3 | NSF-5 | NSF-7 | NSF-8 | NSF-12 |

Lifting capacity | 2m3/h | 3m3/h | 5m3/h | 7m3/h | 8m3/h | 12m3/h |

Diameter of pipe | φ102mm | φ114mm | φ141mm | φ159mm | φ168mm | φ219mm |

Total power | 0.58KW | 0.78KW | 1.53KW | 2.23KW | 2.23KW | 3.03KW |

Total weight | 100KG | 130KG | 170KG | 200KG | 220KG | 270KG |

Hopper volume | 100mm | 200mm | 200mm | 200mm | 200mm | 200mm |

Thickness of hopper | 1.5mm | 1.5mm | 1.5mm | 1.5mm | 1.5mm | 1.5mm |

Thickness of pipe | 2.0mm | 2.0mm | 2.0mm | 3.0mm | 3.0mm | 3.0mm |

Outer diameter of screw | φ88mm | φ100mm | φ126mm | φ141mm | φ150mm | φ200mm |

Pitch | 76mm | 80mm | 100mm | 110mm | 120mm | 180mm |

Thickness of pitch | 2mm | 2mm | 2.5mm | 2.5mm | 2.5mm | 3mm |

Diameter of axis | φ32mm | φ32mm | φ42mm | φ48mm | φ48mm | φ57mm |

Thickness of axis | 3mm | 3mm | 4mm | 4mm | 4mm | 4mm |

With professional in bulk powder handling systems,auger conveyor design and auger conveyor systems, Niel machinery is a professional auger conveyor manufacturers,we provide powder screw conveyor for sale, auger conveyor for sale, screw auger conveyor for sale and etc,want to know more,please contact us.